USA Methacrylate Butadiene Styrene Industry to Reach USD 710 Mn by 2035, Driven by Construction and Packaging Demand.

Industrial innovation and polymer integration push demand 45.3% higher; Midwest leads with 4.2% CAGR

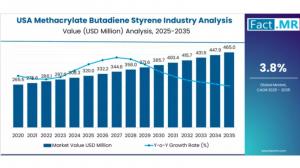

ROCKVILLE, MD, UNITED STATES, November 13, 2025 /EINPresswire.com/ -- The USA methacrylate butadiene styrene industry is on a steady upward path, projected to expand from USD 320.0 million in 2025 to approximately USD 465.0 million by 2035. This marks an absolute increase of USD 145.0 million, translating into total growth of 45.3% at a CAGR of 3.8%. Rising demand from the automotive sector, which accounts for 48.7% of total MBS consumption, and continued innovation in polymer technologies are shaping the next decade of industrial growth.As American manufacturers double down on lightweight, impact-resistant materials, MBS is becoming central to industrial and automotive formulations. Companies are modernizing production lines to integrate advanced polymer systems that enhance both performance and sustainability.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11361

Fast Facts

Market size (2025): USD 320.0 million

Forecast (2035): USD 465.0 million

CAGR (2025–2035): 3.8%

Leading application: Automotive (48.7%)

Top growth regions: Midwest (4.2% CAGR), West (4.1%), Northeast (3.5%)

Major players: Dow Inc., BASF SE, LG Chem, Sumitomo Chemical

What’s Winning, and Why

U.S. manufacturers are favoring performance polymers that combine clarity, durability, and cost efficiency.

Product leader: Automotive applications dominate due to the need for durable, impact-resistant polymer components.

Form leader: Powder form (67.3%) wins on processing efficiency and scalability.

End-use leader: Automotive manufacturers (52.4%) lead adoption, integrating MBS into components for performance and weight balance.

Where to Play

Channels: Direct sales and industrial distributors remain primary routes, while partnerships with polymer converters are rising.

Regional focus:

Midwest (4.2% CAGR): Strong concentration of industrial manufacturers and polymer processors.

West (4.1% CAGR): Expanding chemical infrastructure and innovation clusters in California and Arizona.

Northeast (3.5% CAGR): Integrated supply chains support steady industrial adoption.

South (3.3% CAGR): Access to petrochemical feedstocks enhances cost competitiveness.

What Teams Should Do Next

R&D

Develop next-generation polymer modifiers with improved optical and mechanical stability.

Test low-emission and recyclable MBS blends to align with sustainability goals.

Marketing & Sales

Target automotive and packaging OEMs with performance-based case studies.

Position powder-form MBS as a cost-efficient solution for processing scale-up.

Regulatory & QA

Standardize compliance protocols for automotive-grade MBS materials.

Expand quality control systems for consistent industrial-grade performance.

Sourcing

Strengthen partnerships with domestic resin suppliers to reduce dependency on imports.

Secure feedstock stability through long-term contracts in the Midwest and Gulf regions.

Three Quick Plays This Quarter

Launch a technical partnership with a leading automotive OEM for impact-modified PVC.

• Pilot a low-emission MBS production line in Western facilities.

• Run a regional marketing campaign highlighting powder-form scalability for manufacturers.

The Take

As U.S. industries move toward durable and high-performance materials, methacrylate butadiene styrene is evolving from a niche polymer to a core industrial enabler. Its role in enhancing automotive, electronics, and construction products positions it at the center of America’s manufacturing modernization. In an era defined by precision, sustainability, and reliability, MBS continues to deliver the clarity, toughness, and consistency that industrial buyers demand.

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/11361

Check out More Related Studies Published by Fact.MR Research:

Methacrylate Butadiene Styrene Market - https://www.factmr.com/report/1178/methacrylate-butadiene-styrene-market

Styrene Butadiene Rubber (SBR) Market - https://www.factmr.com/report/styrene-butadiene-rubber-sbr-market

Methacrylate Monomers Market - https://www.factmr.com/report/methacrylate-monomers-market

1,3 Butadiene Market - https://www.factmr.com/report/3783/1-3-butadiene-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.